Intumescent Coatings – explained

Colm McGrath • June 6, 2020

Intumescent Coatings including Paint and other specialist coating systems provide protection from fire to structural steel.

Often confused as ‘fire rated paint’. The Intumescent coating acts very differently to other fire rated systems in such that it isn’t designed to stop the spread of fire. In fact Intumescent Coatings are designed to limit the heat impact upon the structural steel. Therefore Intumescent coatings are more of a ‘Structural’ building element than they are ‘spread of fire’.

Therefore the design considerations are very different to other passive fire elements and considerations are a lot different.

There is a lack of experience in design in NZ with regard to Intumescent Coatings and Contego are proud to state that we have extensive knowledge of Intumescent Coatings and Steel protection systems including which manufacturers products apply best in different design scenarios.

FPANZ is soon to release an Intumescent Coatings Code of Practice which we hope will rectify a lot of the non-compliances currently in practice in New Zealand buildings.

A couple of key early pointers to consider with regard to Intumescent coatings:

- Intumescent Coatings are designed to limit the heat upon the steel members – therefore a piece of steel may get hot & heat up but not allow the spread of flame through. The heat upon the steel will soften the steel & reduce its structural capacity. Therefore we are wanting to limit the heat upon the steel to ensure the structural integrity of the steel member stays within design parameters from a Structural aspect.

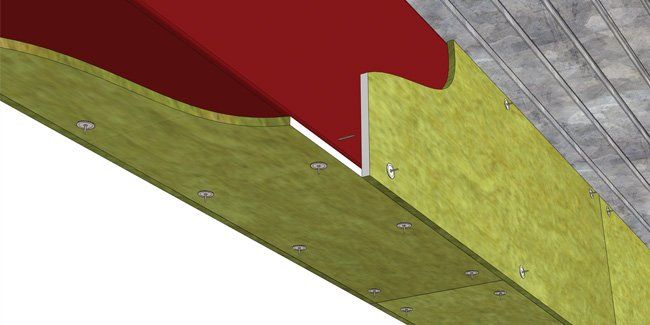

- Intumescent coatings work by expanding under heat & insulating the steel from the heat – therefore if the coating can’t expand it won’t be able to insulate the steel member, meaning timber blocking & linings can’t be applied hard over intumescent paint. Think of it like a life jacket on a plane – if the life jacket can’t inflate it is no good to you.

- Application climatic conditions will impact on the compliance of the intumescent paint – very strict application criteria should be followed and QA records kept

- Quality Assurance at all stages of Intumescent Coatings is critical. Including design, application, completion. No records means there is risk that the design or application is wrong and compliance could be jeopardized.

- Design phase – if Intumescent coatings aren’t considered in the design phase then it is too late to get it right. Decisions will already have been made that will jeopardize your projects compliance and result in non-compliances and cost headaches.

The Passive Fire Protection Intumescent Coating Code of Practice suggests that this should be a collaborative effort between all design consultants to ensure all aspects are considered. This way of thinking is no different to any other collaborative effort in designing a building whereby multiple consultants need to talk & collaborate on a solution.

South Island passive fire protection contractor Contego today announced that it will continue its business expansion by opening a new base in the North Island in December 2021. Located in New Plymouth, the branch is expected to employ 10 persons over the next 24 months. The business currently employs 35 personnel between its bases across the South Island.

I’m sure I’m not the only one that is experiencing weekly headaches with freight delays and lead time materials. What was once available down the road, can now be a lengthy delay to get a hold of it. The feedback I am getting from suppliers and contractors is that the worst is not over, and we should be planning to deal with this for the remainder of this year.

With the current codes of practice and Passive products annual renewal being worked through the issue of Tested vs Assessed is constantly brought up in conversation. NZBC accepts the use of AS4072.1 Assessments as a way of showing compliance as an equal with a tested solution in accordance with AS1530.4.